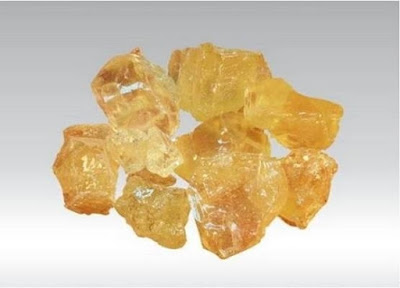

Phenolic resins are thermoplastic polymers that are highly resistant to heat and electricity. Molding materials, abrasives, adhesives, laminates, friction materials, and insulators are all examples of popular applications. Phenolic resins such as resol and novolac are two examples. In normal conditions, resol is made with excess formaldehyde, but in acidic conditions, novolac is made with excess phenol.

Adhesives made with phenolic resins and neoprene rubber have strong thermal stability (service temperatures up to 95 °C) and hardness. The

phenolic resin's structure has been connected to adhesive properties, particularly tack and peel strength. Toluene or MEK-based solutions or films are available for the systems. Although there are formulations that cure at room temperature, most adhesive films cure in 15–30 minutes at 90–250 °C. They are attached to metal, wood, and plastics.

Phenolic resins are ideal for high-temperature applications requiring parts to meet fire safety requirements. Electronics, ballistics, mine ventilation, offshore water pipe systems, aircraft, rail, and mass transit are just a few of the applications for phenolic resins. Low density (weight efficient), low thermal conductivity, excellent corrosion and chemical resistance, a high strength-to-weight ratio, improved design flexibility, cost-effective production of complex 3D structures, excellent fatigue and impact properties, improved acoustic performance, radar/sonar transparency, and low maintenance are just a few of their key characteristics.

Phenolic resins are made from formaldehyde and phenol. Under acidic conditions, phenol reacts with less than equimolar amounts of formaldehyde to produce novolac resins, which contain aromatic phenol units linked mostly by methylene bridges. Novolac resins are heat resistant and can be cross-linked with formaldehyde donors like hexamethylenetetramine to cure them.

Additive and reactive flame retardants can be used to treat phenolic resins when they need to be flame retardant. Some of the reactive flame retardants utilised in phenolics include tetrabromobisphenol A, different organic phosphorus compounds, halogenated phenols, and aldehydes (e.g. p-bromobenzaldehyde). Phosphorus can be added to the phenolic resin by a direct reaction with phosphorus oxychloride. Inorganic substances like boric acid can also be introduced into phenolic resin through a chemical process.

Comments

Post a Comment