Revolutionizing Healthcare: Unleashing the Potential of Stem Cell Therapy

|

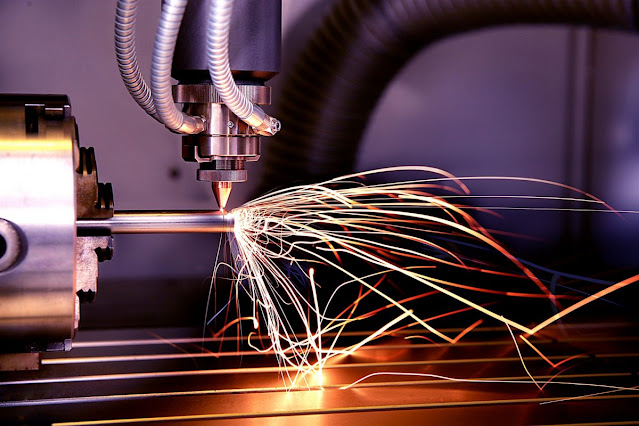

| Industrial Laser Systems |

In the world of manufacturing,

precision is paramount. The demand for high-quality, intricate products has led

to the development of cutting-edge technologies, and one such innovation that

has revolutionized the industry is industrial laser systems. These systems

utilize the power of lasers to perform a wide range of tasks, from cutting and

welding to engraving and marking, with unparalleled precision and efficiency.

Industrial

Laser Systems have become an indispensable tool in modern manufacturing

processes. The key advantage of these systems lies in their ability to generate

intense beams of light that can be precisely focused onto a small area. This

concentrated energy allows for precise material removal, ensuring clean and

accurate cuts even in the most intricate designs. From automotive and aerospace

industries to electronics and medical device manufacturing, industrial laser

systems have found applications across various sectors.

One of the primary uses of

industrial laser systems is laser cutting. This technology enables

manufacturers to cut through various materials, including metals, plastics, and

composites, with exceptional precision. The high-energy laser beam vaporizes or

melts the material along the designated path, creating smooth edges and

minimizing the need for secondary finishing operations. The flexibility of

laser cutting systems allows for the production of complex shapes and contours

that would be challenging to achieve using traditional cutting methods.

Another crucial application of

industrial laser systems is laser welding. By directing a laser beam onto the

joint between two pieces of metal, these systems can create strong, reliable

bonds without the need for additional materials or heat-affected zones. Laser

welding offers numerous benefits, including reduced distortion, enhanced

precision, and improved overall product quality. It is widely used in

industries such as automotive, aerospace, and electronics, where the demand for

lightweight and durable components is high.

Industrial laser systems are also

used for engraving and marking purposes. With their ability to precisely remove

material from a surface or alter its properties, lasers can create permanent

markings, logos, and serial numbers on a wide range of materials. This

capability is invaluable in industries where traceability and product

identification are essential, such as electronics, medical devices, and

packaging.

Moreover, industrial laser

systems have been instrumental in driving advancements in additive

manufacturing, commonly known as 3D printing. By utilizing lasers to

selectively melt or solidify layers of material, these systems can build

complex three-dimensional objects with exceptional precision. This technology

has opened up new possibilities in rapid prototyping, custom manufacturing, and

even the production of intricate biomedical implants.

Industrial laser systems have

unleashed cutting-edge technology in precision manufacturing. Their ability to

deliver focused, high-energy beams of light has revolutionized processes such

as cutting, welding, engraving, and additive manufacturing. With their

exceptional precision, versatility, and efficiency, these systems have become a

vital tool across various industries. As technology continues to advance,

industrial laser systems are likely to play an even more significant role in

shaping the future of manufacturing, enabling the creation of increasingly

intricate and high-quality products.

Comments

Post a Comment